Two widely used protocols stand out in building automation: Modbus and BACnet. Both protocols facilitate the exchange of data across various devices and systems, but they serve different purposes and environments. Understanding their differences and how gateways can bridge the gap between them is crucial for optimising operations in diverse settings. This could be the key to saving you money, energy, and effort with laborious tasks.

What is Modbus?

What is Modbus?

A Modbus interface is a serial communication protocol initially developed in the late 1970s for industrial applications. It allows communication between automation devices such as programmable logic controllers (PLCs), sensors, and control systems within a given network. Modbus is primarily used in manufacturing and process industries due to its simplicity and reliability.

There are two common versions of Modbus gateways these being Modbus RTU/ASCII, which are serial-based protocols that operate over RS-232 or RS-485 connections, offering cost-effective and efficient communication; and Modbus TCP, which operates over Ethernet and allows devices to communicate across larger networks with higher speeds and improved scalability.

What is BACnet?

BACnet (Building Automation and Control Network) is an open protocol designed specifically for building automation. It enables various building systems such as HVAC, lighting, security, and fire detection to communicate seamlessly, regardless of manufacturer.

BACnets can operate over different transport layers, including BACnet/IP, which uses standard IP networks for fast and scalable communication; and BACnet MS/TP, which is a serial protocol suited for smaller-scale, cost-effective applications.

| Feature | Modbus | BACnet |

| Primary Use | Industrial automation | Building automation |

| Communication Type | Serial (RTU/ASCII) and TCP/IP | Serial (MS/TP) & IP |

| Data Representation | Registers (numeric values) | Objects (structured data) |

| Scalability | Limited in serial; better with TCP | Highly scalable with BACnet/IP |

How Gateways Enable Communication Between Modbus and BACnet

How Gateways Enable Communication Between Modbus and BACnet

In mixed environments where industrial and building automation systems coexist, Modbus-to-BACnet gateways provide seamless integration by converting data between the two protocols. These gateways enable Protocol Translation which converts Modbus register-based data into BACnet object-oriented data and vice versa; Interoperability (the ability for computers to exchange and make use of information) which allows legacy Modbus devices to communicate with modern BACnet systems; Network Expansion that bridges different network types such as serial-based Modbus RTU with BACnet/IP; and Centralised Control to integrate industrial control systems with building management systems for enhanced efficiency.

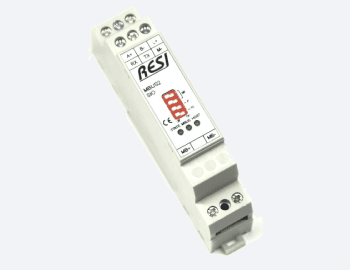

One such example of a Modbus is the Resi Modbus (mbus2-sio) Gateway, which offers a reliable solution for integrating M-Bus smart meters into Modbus-based systems. With support for up to 40 Modbus registers and communication via RS232 or RS485 interfaces, this gateway enacts smooth data exchange while offering galvanic isolation for enhanced protection. It is an ideal choice for environments requiring the seamless integration of energy metering devices into Modbus networks.

Choosing the Right Gateway

From an Mbus to BACnet gateway, selecting the appropriate option depends on factors such as:

Device Compatibility: Ensure it supports the specific Modbus and BACnet versions in use.

Network Size and Complexity: Consider the number of connected devices and the desired level of scalability.

Environmental Conditions: Some gateways offer rugged designs for harsh industrial environments.

While Modbus and BACnet serve different applications, gateways provide an essential bridge between the two, ensuring seamless communication and integration. Whether you're managing industrial equipment or building automation systems, choosing the right gateway can help unify operations, enhance data flow, and improve overall efficiency.